The GasGun® system is a solid-propellant well-stimulation device based on proprietary ballistic technology from the U.S. military. It incorporates the most advanced design on the market with the use of progressively burning propellants that have been proven by independent research to be many times more effective in creating fractures and increasing formation permeability.

The Kraken® propellant-enhanced perforating gun is designed to overcome the reservoir-damaging effects of conventional perforating gun systems. The propellant boosters contained inside the Kraken gun are based on the same progressively burning propellant technology used in our GasGun® stimulation tools. Progressively burning propellants have been proven by independent research to be many times more effective in creating fractures—a key advantage that sets our tools apart from the competition.

The QRM6 is a Standard Quartz Crystal Pressure and Temperature Downhole Memory Gauge. It uses ASIC driven Multichip Module (MCM) that can operate up to 220°C. The MCM is a hybrid-type electronic board and is mounted on shock absorbers for better performance and reliability.

The CGM6 is an Advanced Quartz Crystal Pressure and Temperature Downhole Memory Gauge. It uses ASIC driven multichip module that can operate up to 220°C.

The reliability and robustness of CGM6 are one of the most important contributor to Metrolog’s memory tools reputation.

Tredwell is introducing the shortest available Array PL tools on the market, measuring just 3 feet in length with a minimum outer diameter of 1.69 inches and a maximum opening of 6.5 inches. These tools are configured with optical probes and micro-spinners for accurate holdup and velocity measurements. They provide the capability to observe fluid flow regimes and movements around the wellbore, allowing for direct holdup calculations that facilitate quick analysis.

We are introducing a series of innovative gas-tight non-return valves designed to address the current challenges in drilling operations. Our product line includes the DT Surface Flapper Safety Valve and the DT Flapper Safety Valve, both of which prioritize safety and efficiency through improved design and engineering.

The DT Surface Flapper Safety Valve and DT Flapper Safety Valve are advanced gas-tight non-return valves designed to enhance safety and efficiency in drilling operations. The DT Surface Flapper prevents backflow and features superior sealing and washout resistance, ensuring reliability and extending service life and primarily for use in BHA. The DT Flapper Valve offers versatility, improved flow characteristics, and enhanced pressure response and can used anywhere in the drillsting. These valves undergo rigorous testing to ensure high performance, allowing operators to trust their well control systems. By focusing on cost-effective, high-value innovations, we address the critical challenges in modern drilling operations. Investing in these valves will enhance well control and provide peace of mind for your drilling projects.

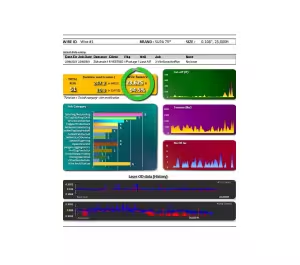

We are embracing digitalization in our products and services by developing solutions tailored to our clients’ needs, with a focus on improving and optimizing their operations. Our proprietary Tredwell Well Intervention System is a groundbreaking digital platform that transforms traditional practices into a more efficient method of managing data. It is the first of its kind in local slickline operations.

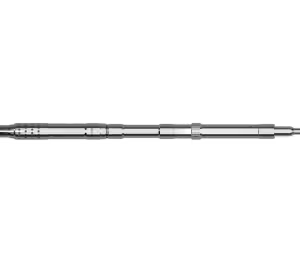

Our Dual Sleeve Autofill Sub (DSA) is currently the most popular option among Malaysian customers. When running in a hole, the DSA runs above a barrier plug to allow the tubing to fill automatically. With a simple design that prevents fluid flow from tubing to casing, userscan test their tubing multiple times as long as the shear pressure of the lockout piston is not exceeded.

Our Completion Overshot represents a significant technological advancement for the company. This innovative equipment features a breakthrough design capable of swallowing and securing existing in-hole “old” tubing, specifically tubing stump. To enhance operational efficiency and adaptability, the Completion Overshot is optionally available withvarious bottom guide, self-alignment and wiper ring features. These additional functionalities further optimize performance in diverse well conditions. The Completion Overshot can incorporated advanced seal technology to ensures reliable pressure containment that follow body connection up to 5,000 psi, effectively mitigating the risk of leaks and maintaining well integrity.

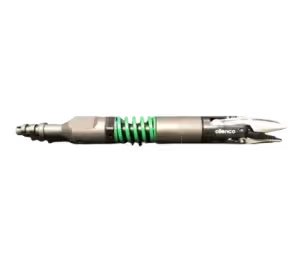

The Oilenco Wire Roller Brush has been designed to offer a slickline deployed method of scale removal and cleaning of completion assemblies.

The brush provides an effective means of cleaning, deburring and removing scale from a range of completion components, varying from safety valves to landing nipple seal bores. The wheels offer rotation in both directions which allows the tool to effectively remove scale and maximise deburring of damaged seal bores.

The spring-loaded wire wheels ensure no scoring occurs to the seal bores, whilst providing a honed type finish and 360° coverage.

The Tubing Hanger Plug has been specifically developed to provide a reliable isolation barrier for both subsea and platform tubing hangers.

The plug has been designed in accordance with API14L specification, is V1 qualified and has the ability to provide a bi-directional pressure rating of up to 15,000 psi at 150°C.

The Soak Sleeve and Syringe provides a means of precisely spotting a concentrated chemical solution across a downhole safety valve. Initially, the Soak Sleeve is deployed across the downhole safety valve, creating a sealed annulus between the sleeve and safety valve. The syringe is then filled with the relevant chemical and deployed into the soak sleeve. The chemical is then expelled into the annulus and left to soak across the affected areas of the safety valve. Leaving the sleeve in place, additional syringe runs can be completed with fresh chemicals as required.

A one-run syringe system is available for subsea operations.

The Oilenco Scraper Tool is a fully adjustable downhole scale & debris removal tool. The tool can be set to any specific diameter and precisely adjusted to suit the downhole conditions. Furthermore, the Scraper Tool has a unique ‘anti jamming’ feature that allows the cutting teeth to ‘relax’ during upwardmotion.

Scraper Tools are nominally sized to suit standard tubing sizes and are supplied with a set of cutting teeth to cover the entire tubing range plus any common restrictions. The Scraper Tool effortlessly removes small amounts of material with each pass. Not only is this method more efficient, it also prolongs the sharpness of the cutting teeth.

The Downhole Safety Valve Protection Sleeves are designed to provide a temporary means of holding open the flapper in the subsurface safety valve whilst also protecting the seal bores from subsequent runs in hole.

With a sleeve installed, this ensures the flapper is securely held open, eliminating the risk of closure on the wire allowing for runs to be deployed safely beyond the safety valve.

From a standard snap-in collet to the more advanced lock-in type mechanisms, the protection sleeves can support all intervention methods and can be deployed on slickline, e-line, coiled tubing and real-time coil tubing (RTC).

Our extensive range of protection sleeves are available in a variety of ID’s from standard bore to large bore and super thin wall, and are compatible with third party tooling.

We can also provide specialised support tooling including lifting clamps, deck stands and C-plates to ensure safe handling of the sleeves.

The pressure wave valve(PWV) is an intervention free, open-on-demand, equalising device that can befitted to lock mandrels and bridge plugs to provide a large through-bore once activated. The application of PWV include plug and abandonment workscopes, mew completions and workovers.

With excellent pump through capability, the system functions purely on amechanical hydraulic principle. The internal mechanism operates only when it senses a ‘wave’ of applied pressure i.e. starting from a low pressure range, increasing to an upperpressure, and then returning back to alow pressure. This sequence counts as one ‘wave’. By repeating this sequence several times to the pre-set values, the valve will open and provide alarge through-bore.

The Oilenco OneDrift is a simple, yet effective solution to well bore drifting. The OneDrift is run into the well on wireline, tractor or coiled tubing.

When the tool encounters a restriction within the well, jar action or downward force is applied until the restriction has been passed. This reduces the tools outer diameter in 0.100” increments, allowing access beyond the restriction. The same process is applied to overcome further restrictions within the wellbore, allowing the target depth to be achieved in a single run. Upon tool retrieval the drift diameter is measured to verify the minimum well bore restriction.

For unknown restrictions, i.e. scale deposits, collapsed tubing, etc., the tool will operate in the same manner. There is no correlation between the number of jar impacts applied to activate the tool, it will simply continue to reduce in diameter until the restriction has been passed.

As the outer diameter is adjusted during the run, the drift diameter is measured to verify the minimum wellbore restriction upon tool retrieval.

The Hybrid Plug provides a secure, high performance well isolation barrier, when compared to conventional plugging methods, it offers significant operational advantages and improved integrity assurance. The Hybrid Plug combines the simplicity of a regular blanking plug, but with the integrity assurance of a bridge plug. The Hybrid Plug is available in two version,Annulus Version and Production Bore Version.

For example, during a tree change out, the production bore require the installation of either a blanking plug (set in a nipple profile) or a bridge plug. Either method has distinct advantages and disadvantages. Blanking plugs have the obvious advantage of simplicity, both in terms of deployment and method of sealing (V Packings). The disadvantage of a pressure test from above on a V packing is that it does not prove pressure integrity from below. Alternatively, a bridge plug features an expanding element, therefore a pressure test from above is reasonable assurance of pressure integrity from below. The disadvantage of setting a bridge plug is that they normally require the use of relatively sophisticated setting equipment and skilled personnel.

The Hybrid Plug is set and retrieved on slickline and uses an existing landing nipple profile within the tubing hanger. Using a dedicated mechanical setting tool, the plug is initiallylocked into the nipple profile.

The Hybrid Plug can also be crossed over to all manner of accessories such as pump open plugs, remotely activated equalising devices to suit different customer requirements.

The Oilenco Fishing Claw was designed by our engineers as a versatile and robust tool for fishing a variety of difficult downhole targets.

The Wireline Retrievable Subsurface Safety Valve(WRSV) isaself-equalising, flapperty pesafety valve intended to be installed in side a tubing retrievable subsurface safety valve(TRSSSV) that is no longer functioning correctly. The WRSV is available in different size options:

The Oilenco UniLOT (Universal Lockout Tool) is designed to permanently lock a tubing-retrievable subsurface safety valve (TRSSSV) in the open position, ensuring that the flapper does not obstruct its operation.

The mechanical UniLOT secures the flow tube in a position that stops the flapper from closing after the control line pressure is released.When the Oilenco UniLOT is deployed, downward jarring deforms the walls of the flow tube, permanently preventing it from returning to its original position and ensuring that the bore of the TRSSSV remains unobstructed.

The Hybrid Safety Valve Straddle System was developed to overcome the limitations of WRSSSV systems, boasting a unique sealing system that expands into the seal bore providing many operational benefits.

The Flapper Check Tool is designed to ensure that the flapper is functioning correctly before lowering a tool string through the safety valve. If the flapper is only partially open, there is a heightened risk of severing the wireline, which could result in the accidental loss of the tool string downhole.

The Flapper Check Tool mitigates this risk by confirming the status of the flapper before introducing wireline into the well.

For situations where the tubing retrievable subsurface safety valve (TRSSSV) flow tube is suspected of not returning to its original position during the closing of the safety valve, the Exercise Tool can be used to add additional mechanical force to assist the movement of the flow tube.

The Exercise Tool provides a means to grip and pull the flow tube within the TRSSSV. By running the tool, additional upward movement can be created to force the flow tube back to its original position. The tool allows for light upwards jarring to be applied directly to the flow tube to overcome any stubborn debris/scale deposits that may be hindering the closure of the safety valve.

The tool uses a series of steel balls that provide sufficient grip to the inner bore of the flow tube without marking or deforming it. Because the Exercise Tool does not rely on existing exercise profiles within the TRSSSV, it offers far more versatility and can suit a wide range of safety valve models from various manufacturers.

The tool incorporates an adjustable no-go ring that allows the tool to be positioned at the exact position within the flow tube immediately above the closed flapper position.

Unique to our Exercise Tool is the ability to perform a primary drift run. This setup confirms the tool can successfully set and released without physically gripping the inside of the Flow Tube. Although this can be seen as an additional run, it does provide added reassurance that the Exercise Tool can be located inside the TRSSSV at the correct position and can also successfully release.

We can supply Exercise Tools to suit most types of safety valves found in 5-1/2” and 4-1/2” completions and have a team of highly competent offshore specialists to support your operations.